This page details the 2013 re-opening of EvilDeadChainsaws.com, with new and revised chainsaws. So just to say up front, back in 2005 when I was first prototyping the original saws, I had only been working in special effects for a few years so many of the processes, tools, and machinery I was using were quite new. Now I'm far more experienced both in terms of general processes, and making Evil Dead Chainsaws specifically, so these new saws are very much improved over what I used to sell.

I started the prototyping process at the start of April 2013 lining up three orders to make at the same time, completing those three orders nine weeks later at the start of June. Now, you might assume that three orders at £550 a-piece equals mega profit! Not exactly, all of that went out in materials expenses. For example, the blood finish is actually a specific type of enamel varnish, in order to get the right colour you need to mix together stock blue, yellow and red colours. A 500ml bottle of each colour is about £14, so you're talking £42 just for the varnish to give the blood finish alone. Obviously that varnish-mix will last for a number of saws, but I still have to buy in the first place. Another example is the revised grill design, in order to precisely give 9 channels & 10 ridges across the 68mm space, I needed a 9/64" milling bit. £21.59 for that one-use-one-thing thank you very much. Actually as well as the three orders I still had to spend some of my own money to get this going. Anyway it's all up and running now. You can see some of my Prototyping & Production photos below.

Prototyping & Production

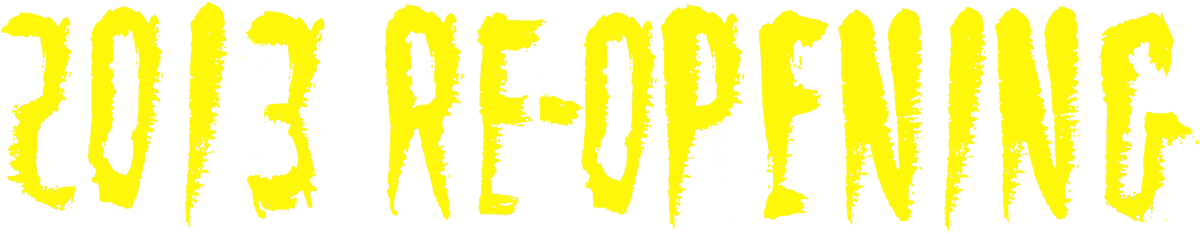

The original Homelite XL engine block

removed from the plastic body

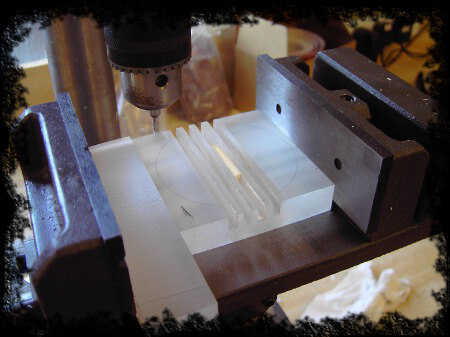

The moulded 'fake' engine block plate

with moulded muffler and real guide bar

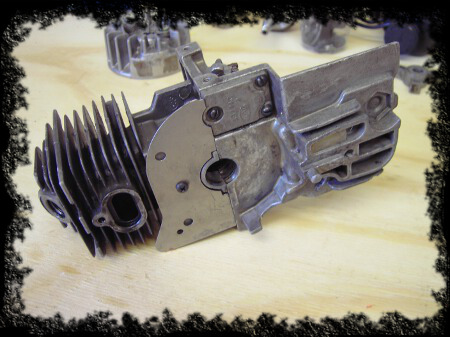

Setting up the pillar drill to mill

a solid piece of clear acrylic

The much simplified fuel/oil lid assembly

completed & ready for moulding

An original Homelite guide bar (left)

with a paint-stripped bar (right)

In-progress thickening of the body

section, alongside lid prototyping

Some resin cast pieces; the

side 'C' handle & lid assembly

My replica 'fake' engine block plate

completed & ready to mould

The 'fake' engine block plate with

resin moulded body, muffler & sprocket

The completed milled & dome sanded

acrylic grill piece ready for fitting

The gill side of the body, showing the

lid assembly insterted in place

Two paint stripped guide bars

after being age treated

The inside of the saw, showing the

horizontal handle & 'fake' engine plate

Three sets of cast pieces, painted

and ready for final assembly

Testing the 'fake' engine block plate

assembly to the other parts

Adding textured grime to the engine

body, muffler & sprocket area

Fitting the acrylic grill to the original

Homelite XL body section for moulding

The resin cast lid assembly, painted

and ready for final fitting

A stripped & age treated

guide bar close-up

The inside of the saw, with the

cast resin sections assembled

My current workshop, about half

the size of the previous one

What Are The New Revisions & Changes

Below is an outline of some of the revisions and changes from my previous 2009 chainsaws. For the most part, the saws look virtually identical from the outside, but there have been some tweaks. The biggest changes are the interior construction; the stuff you don't see. Further down you can see my first three 2013 chainsaws, all 'Cabin' model saws; the first with no blood, just an oily dirty finish, second with a light splattered blood finish, and the final set of photos show a saw with the standard clotted dried blood finish.

A generally stronger construction

These saws are much stronger than my previous saws. This is not to say that they were poorly made, they were more than adequate for the odd fancy dress party, but when I supplied chainsaws to the Evil Dead The Musical first time round, some problems became quickly apparent. This was basically because the original chainsaw had a plastic outer body which was fixed to a solid engine block inside. This made the whole thing very strong. I had dismantled and moulded the body sections virtually exactly as they were originally without thickening or modifying them too much, which meant portions of the saw were quite weak as they had no support on inside from the engine block (as the saw was hollow), which ordinarily wouldn't be a problem as most people would not be bashing about too much, but the musical saws were different. I mean they really really took a hammering. Over the course of about eight saws supplied over about a year, a number of progressive modifications were made to each saw. These new range of saws incorporate all those modifications, along with addressing a number of niggling issues present on the old saws. It was those progressive modifications that made each consecutive saw harder and harder to make, as once the resin castings came out of the mould, each modification beyond that would mean extra time, so two modifications meant extra time again, and so on, which is one of the main reasons why I stopped making them in the first place, they were just taking longer and longer. Looking back, what I should have done is what I'm doing now which is to take all the modifications and start from scratch, and at the time I was happy to leave it behind and move on to other projects.

A longer lid

Making these replicas has always been a fine line between creating something as exact to the screen version as possible, while having something that will stand up and look really good under close scrutiny. Basically the screen chainsaws have dictated the overall look of the saws, and a real homelite XL saw has been used to fill in all the fine detail. The lid is something which has been changed from the previous chainsaws. Before, the end of the lid was just about flush with the back of the saw body. This was a mistake, the lid should have been about an inch longer at the back so it overhangs the chainsaw body, even though this makes them look too long. I could shorten it and it would look much better, but it wouldn't be a replica. There are a number of places in the movie where you can see this, especially now with the Blu-Ray release (which I didn't have first time round). Maybe this was because there wasn't enough room for Bruce's hand along with the motor & electrics in there, so elongating the lid allowed them to move Bruce's hand further back. Anyway, so actually it was my previous lid that was too short. This has now been corrected. The screen used saw also has two aluminum brackets, one either side of the lid, holding the lid on at the back of the saw. I've not included these as you only see them in one shot in the movie, and they look quite messy. I may reverse this decision at some point, but that's where I am at the moment.

More accurate muffler assembly

On the old saws in certain photos on the website you can see that the muffler (the black box on the side), was simply fixed to a flat black plate made as part of the body section. On the real saw, this section looks little different, and more precisely replicating this this was one of the main cosmetic modifications. The fake engine plate now stretches from the front of the saw where the blade is, to the back of the saw where your hand goes in, all down the right-hand side. This encompasses a fair replica of the engine section to which the black muffler would attach. Without the depth, it's the closest approximation I can make. The muffler itself is a bit of a tricky one and something that was always difficult on the previous saw, as it's so thin. When I've done is to basically make the whole thing solid as far as can be, while leaving holes to make it look like it's still hollow. On the workshed saw, the muffler is the right way round. On the Army of darkness saw, only one side of the muffler is used, but on the cabin saw, at various points in the film the muffler is shown both ways round. I'm intending to sell the cabin saw with the muffler the wrong way round, that is to say opposite to the way round the muffler would have been on the original working Homelite saw. There is no easy way of making the muffler reversible so people can choose to have it either way round.

More accurate grill

The previous saw's silver side grill was simply created using a spray paint can lid filled with bodyfiller, and cut the grooves with a file. While it looked okay, it was far from precise. I bought a cross clamp vice, which turns my pillar drill into a small milling machine. This allowed me to cut exact channels resulting in something far more professional. I milled the grill out of a solid piece of acrylic. The grill also was given a slight dome to it, whereas on the old saws, it was flat with a beveled edge. Not only was this probably the most complicated single piece to make, it was also the most easily fuck-up-able, since being milled out of a solid piece of plastic, one wrong measurement could have ruined the whole thing.

Textured grime

On the previous saws, the general grime finish was created using various paints and varnishes, and while it looked good, it was still roughly flat. Upon looking at real chainsaw photos, an oily sawdust mix collects in certain places around the visible portion of the engine block under the chain & sprocket, and around the muffler assembly. This is now added to the replica chainsaws using a paint/sawdust mix to built up a texture to the black oily grime finish making the whole thing look more realistic.

Painted black inside

The interior of the body of the saw has been painted black inside, whereas previously the chainsaws were just left red as they were. Assuming the wearer has a black glove on their hand, the chainsaw should look totally black inside from any angle hiding the fact that someone's hand is inside .

Guide Bar Paint Stripping

The guide bars (the long piece of thick metal which the sharp chain runs around) are bought new with a grey painted finish. Previously, I used to use a belt sander to take the paint down to the metal. As well as being very time-consuming, it also wasn't ideal. Along the length of guide bar there are little indents which are just slightly below the surface of the rest of the guide bar. Getting the entire guide bar down to the metal, meant either standing for ages until the whole of the metal was ground back to these little indents, or invariably giving up before that point. As it's a powder coated finish, is designed to be very hard wearing and really tricky to remove. I found an industrial paint stripper that will allow me to remove it with a few applications. This means the whole guide bar can be taken down to the metal with far less effort, and it looks better as there still indents and bumps on the saw rather than the whole thing being sanded flat.

A 2013 'Cabin' Chainsaw

(No Blood, Just An Oily Dirty Finish)

A 2013 'Cabin' Chainsaw

(With Light Splattered Blood Finish)

A 2013 'Cabin' Chainsaw

(With Clotted Dried Blood Finish)

.jpg)

_01.jpg)

_04.jpg)

_07.jpg)

_10.jpg)

_02.jpg)

_05.jpg)

_08.jpg)

_11.jpg)

_03.jpg)

_06.jpg)

_09.jpg)

_12.jpg)

_01.jpg)

_04.jpg)

_07.jpg)

_10.jpg)

_02.jpg)

_05.jpg)

_08.jpg)

_11.jpg)

_03.jpg)

_06.jpg)

_09.jpg)

_12.jpg)

_01.jpg)

_04.jpg)

_07.jpg)

_10.jpg)

_02.jpg)

_05.jpg)

_08.jpg)

_11.jpg)

_03.jpg)

_06.jpg)

_09.jpg)

_12.jpg)